Development update: FELICE Adaptive Workstation (AWS)

The Institute for Human Factors and Ergonomics (TUD) entered the second phase of development for the Adaptive Workstation (AWS). The goal of the system is to adapt specific workplace dimensions to fit the individual needs of workers in assembly automatically. In FELICE, this includes the adaptation of the work object’s position for two degrees of freedom: height and inclination. Currently, the addition of an adaptive light system to automatically change the local illumination as an additional environmental factor is in development.

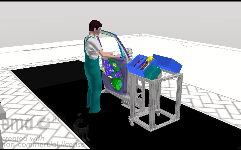

A novelty in FELICE: the prototype is specifically designed for larger work objects, like car doors, at paced assembly lines. The dimensions of these objects exceed the ergonomic grasp spaces of the operators. Because of this multiple repositionings could offer additional benefits to the worker’s postures. Using a motion capture system, it was seen during the first phase of development, that a repositioning of the door based on the anthropometry of the individual leads to a better working posture. For this phase of development, simulation tools have been used to assess the impact of different adaptive strategies. The software ema Work Designer by imk Industrial Intelligence GmbH has been used to model the assembly process and to generate simulated EAWS risk indices and measure assembly times for workers of different body proportions. The findings: the number and timing of adaptation plays a significant role in the productivity of the system.

Furthermore, the adaptive positioning is suited to address differences in workload between workers that result from differences in their anthropometry (body height), making the workplace more accessible. These effects will be evaluated on the physical prototype in the future to derive specific recommendations on the design of adaptive systems.